JL-32(1920LPH) Portable Oil Purifier

- Widely used for industrial oil from transformers, machineries, turbines etc;

- Portable oil purifier for removing particles from used/unqualified oil;

- Cooperation with international&domestic reputed brands;

- Automatic control system, equipped with comprehensive protection mechanism;

- Flow rate 1800LPH to 30000LPH or as requested;

- 13 Years of purifier manufacturing experience;

- Customizable;

- 2 years warranty, 7*24 hours technical support and after services.

For product pricing, customization, or other inquiries:

Description

| Applications

The JL Series Portable Oil Purifier is mainly used to filter the impurities in transformer oil, turbine oil, hydraulic oil, Gear oil, machine oil and other lubricating oils in power plants, power stations, Electrical substation of industrial and mining enterprises, Machine tractor station, petroleum, chemical, metallurgy, machinery, steel, cement, mining, Arms industry and other units. It is an ideal equipment for vacuum oil purifier, turbine oil purifier and other oil purifier as pre primary filtration.

| Features

- Simple structure, filters as filter media.

- No heating, the additives in the oil are well prevented from degradation or deterioration.

- Easy to operate, with simple structure, small volume, lightweight, easy to carry and operate.

- Low operation cost, low maintenance time and cost

- Special boosting type oil pump has strong suction ability and makes the machine to be used in more oil types.

- Low noise, quick and convenient to replace the filter paper.

- High efficiency, can effectively purify the tiny and fine mechanical impurities from oil.

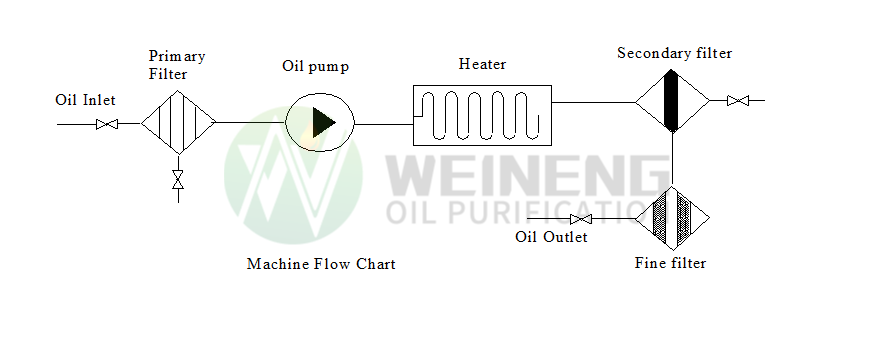

| Flow Chart

| Specifications

| MODEL | LY-30 | LY-50 | LY-100 | LY-125 | LY-150 | LY-200 | LY-250 | LY-300 | |||||||||

| Flow Rate | L/Min | 30 | 50 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||

| Filtration Size | ≥M2 | 0.3 | 0.39 | 1.3 | 1.54 | 1.89 | 2.0 | 2.5 | 3.0 | ||||||||

| Working Pressure | MPa | 0 – 0.5 | |||||||||||||||

| Board Frame Size | MM | 180×180 | 280×280 | ||||||||||||||

| Manual Screw | |||||||||||||||||

| Filter Frame Quantity | 10 | 11 | 12 | 13 | 14 | 17 | 18 | 23 | |||||||||

| Filter Plate Quantity | 11 | 12 | 13 | 14 | 15 | 18 | 19 | 24 | |||||||||

| Filter Paper Size | MM | 185×190 | 285×290 | ||||||||||||||

| Gear Oil Pump | Flow | L/Min | >30 | >50 | >100 | >125 | >150 | >200 | >250 | >300 | |||||||

| Safe Pressure | Mpa | 0.6 | |||||||||||||||

| Power Supply | 380V,3Phase,50hz | ||||||||||||||||

| Viscosity(MM2/S) | ≤46 | ||||||||||||||||

| Noise dB(A) | ≤55 | ||||||||||||||||

| Filtration Precision | ≤1- 3 µm | ||||||||||||||||

| Power | KW | 0.75 | 1.1 | 2.2 | 2.2 | 2.2 | 3 | 3 | 5.5 | ||||||||

| Inlet Diameter | MM | 25 | 25 | 32 | 32 | 32 | 40 | 40 | 50 | ||||||||

| Outlet Diameter | MM | 25 | 25 | 32 | 32 | 32 | 40 | 40 | 50 | ||||||||

| Machine Length | MM | 700 | 750 | 900 | 950 | 1000 | 1100 | 1200 | 1300 | ||||||||

| Machine Width | MM | 300 | 300 | 300 | 400 | 440 | 440 | 440 | 440 | ||||||||

| Machine Height | MM | 720 | 840 | 840 | 840 | 840 | 1000 | 1000 | 1000 | ||||||||

| Machine Weight | KG | 76 | 86 | 130 | 150 | 180 | 210 | 230 | 280 | ||||||||

| Maintenance

- The machine adopts a mechanical purifying way and increases the density of the filter net step by step to improve the precision of filtering. In this way, when the machine is working, the primary filter is easily jammed which causes the quantity of inlet oil to be less than that of outlet oil. Resolving method: remove the cover of primary filter, take out the filter net, and then use the clean oil which is the same type as the waste oil to clear. In this way, the machine can work normally.

- If the oil rises so high when adding the oil, it will cause the temperature of the generator to improve quickly, and the noise of the oil pump increase. Resolving method: 1 work as per the ruled oil raise. 2 work discontinuous.

- The noise of the oil pump is so big. Resolving method: check whether the connecting axes of the oil pump are homocentric. 2 check whether the screw is lax or dropped off. If there is any problem as mentioned above, pls recover it, then the machine can work normally.

- Strictly prohibit lacking phase to avoid burning generator.

- The continuous working hours of the machine can not be over 150 hours, if the machine has working 150 hours without stopping, pls have the machine rest for 2 hours.